It’s a bright Monday morning on the Ards Peninsula as the sun shines down on the rolling rural landscape. Farmland birds skirt between bushy hedgerows and hundreds of happy heads look out at us, waiting for milking time at Glastry Farm.

The dairy farm in Kircubbin, Co Down has been the home of the Taylor family for 150 years. Glastry has been milking cows since 1856, and William Taylor and his son, Gareth are now the fifth and sixth generation working the farm, which is approximately 260ac owned and a further 150ac leased.

William and his wife Cynthia manage the ice cream production side of the business, and Gareth and his wife Liz look after the dairy farm, with its 400-strong herd. It’s a full family affair with Gareth’s three children, Tom, Isla and Amy, also mucking out.

Irish Country Living arrived up to Glastry Farm shortly after Balmoral Show. The team scooped a mighty 1,200 litres of ice cream at Northern Ireland’s largest agricultural show.

It was nearly 20 years ago, in 2007, when the farm diversified into the production of ice cream. “I was standing outside the farm about this time of year and a tanker driver pulled up,” says William. “I asked him, well how’s things? The usual chit chat. He said: very busy, very busy. I’ve got about three loads [of milk] to get rid of today.

“When he was driving down the road, I started to think. It takes two and a half years bringing heifer calves to the stage of actually milking, all the work and planning and preparation and legislation that surrounds producing a fresh product. Then somebody tells me he’s taking it away to get rid of it and what he meant was he was taking it to the processing plant to make powder, butter or something or other.

“That got me thinking. So I took a Nuffield scholarship to investigate the opportunities for agri-food. It involved me visiting parts of what was then the new Europe, like Slovakia as well as countries such as France and Germany, to look at cooperation and farm diversification. I came home greatly impressed.

“I had visited a farm that turned potatoes into vodka and we were on a 3ha farm in Slovenia that produced a range of wines from their vineyard on a hill that I could hardly walk up.”

When William came home, he did a product development programme in conjunction with the Food Technology Centre at Cookstown and a market research survey with the support of Ulster University. Convinced the farm had to develop for the future and get better value from their product, they expanded their milk production unit and launched their ice cream in 2007.

Glastry make about 16 different flavours of ice cream. Pictured is their Chocolate & Mallow. \ Claire Nash

From milk to ice cream

Fresh milk is transferred from the milking parlour to the processing facility on the farm, where it is handmade into about 16 different flavours of ice cream, including a suite of seven sorbets.

William and his team show Irish Country Living around the ice cream plant.

And we’re in luck.

The team are making two sorbets – Pear Pear and Açaí Berry. The latter is a new flavour. We are shown the pasteuriser, continuous freezer, and production room where all the ingredients are weighed out and measured up.

“We try to get our ingredients from local suppliers. Our Irish whiskey flavour uses Dunville’s Irish whiskey. It’s local. The yellowman for our Yellowman Honeycomb comes from Aunt Sandras in Belfast and it has a beautiful chewy toffee flavour,” says William.

“We have plenty of ideas for flavour combinations,” William goes on. “Last autumn, we launched a delicious cherry flavour [Cherry Blossom] and we do a Toffee Apple ice cream for Halloween.”

The weekly ice cream production operates like a well-oiled machine, with about 90 5l tubs of ice cream made in one run. The sorbet is made on different days to the ice cream to avoid cross-contamination. It is also a nut-free site: “we made a decision about seven years ago that we would go nut-free, and it’s actually proved to be commercially attractive for us,” says William.

The introduction of sorbets to the range has also been another strong business decision for Glastry. “Sorbet has moved on from being a palate-cleanser at the start of a meal to actually being a dessert,” says William. “They’re sort of like a lower sugar, lower fat and healthier alternative. It’s good for people who can’t have dairy and they have the highest fruit content currently on the market.”

Glastry’s Raspberry Ruffle and Mango and Passionfruit Sorbet both received a One Star Great Taste Award in 2024. The Mango and Passionfruit Sorbet also received a bronze award in the Irish Quality Food and Drink Awards 2024 and a silver award in the Blas na hÉireann Irish Food Awards 2024.

Wagyu beef

On the other side of the business, Gareth tells us that: “the herd of 370 cows have produced a herd average to end of April 2025 of 841 kgs/cow of fat and protein.” He adds that Glastry has also diversified into Wagyu beef, rearing between 40 and 60 this year.

“We use sexed semen on around 50% of our dairy herd, mating them to pure Holstein-Friesian for heifer replacement.

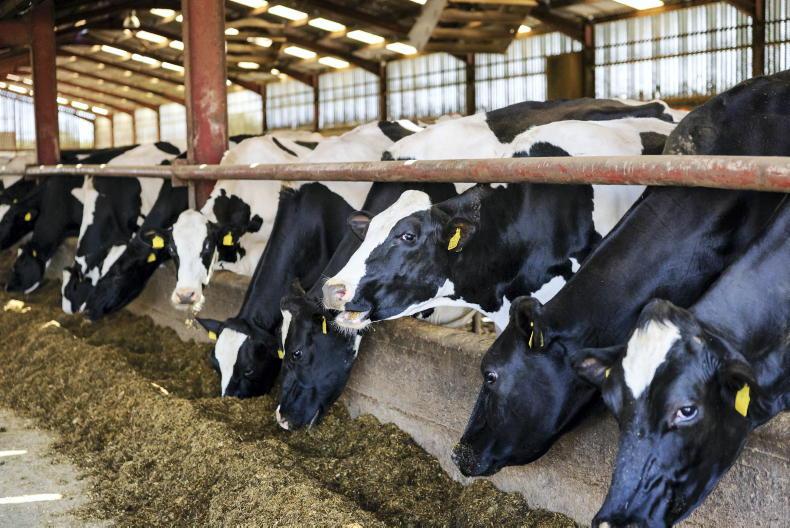

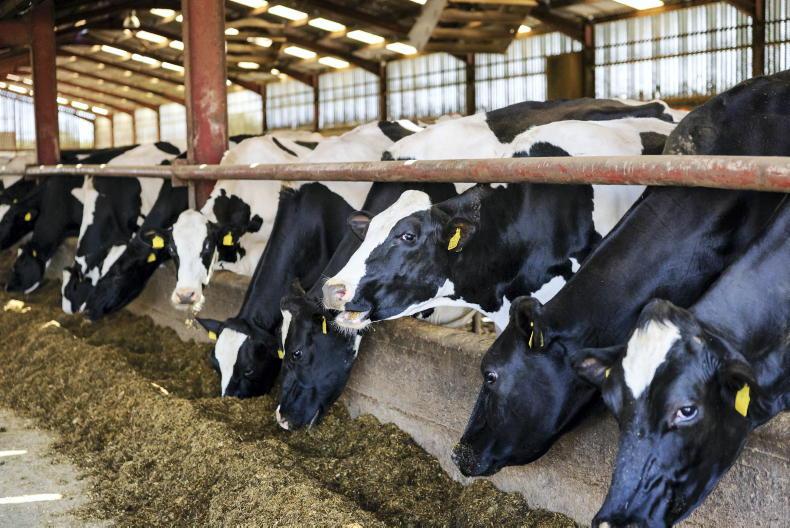

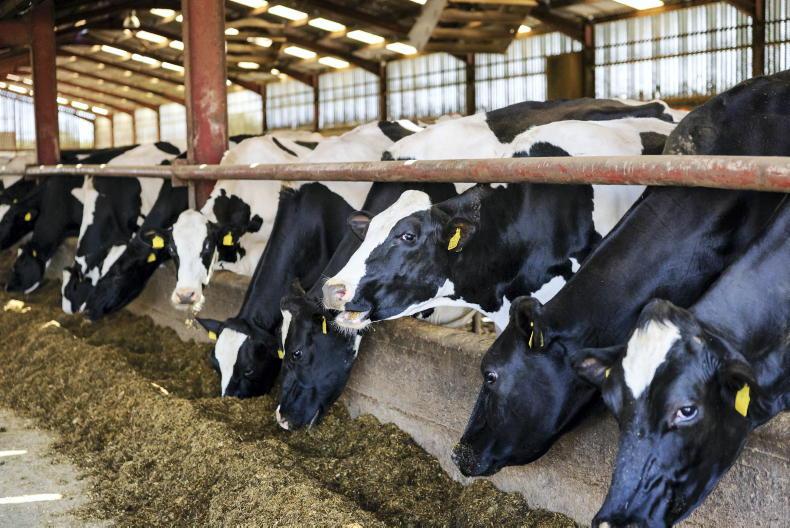

The herd of 370 cows have produced a herd average to end of April 2025 of 841 kgs/cow of fat and protein. \ Claire Nash

The farm dairy has been completely self-contained for a generation. The other 50% of the herd is mated to Wagyu semen and we produce around 150 Wagyu offspring, which are kept on farm until they are six weeks old before moving to a specialist rearer who takes them through to finish,” says Gareth.

As we walk around the farm, William points out the present he bought for each of his three grandchildren six years ago: a pedigree Jersey heifer.

He shows Irish Country Living their current offspring for the 2025 season. They’re a beautiful caramel colour and William’s grandchildren adore them. “They’re a good pet, aren’t they?” he says, laughing. “They’re multiplying quite rapidly and we’re guaranteed heifers. It’s great.”

When asked what is it like running a family business, father and son have no complaints.

“Running a family business is a double-edged sword,” says William. “You can get almost instant decisions at breakfast time for either a day’s work or the following week’s work. Equally, I think because of the generation gap, there’s differences of opinion about what’s important for the family business. I’m very fortunate that we don’t fall out. We’re not at loggerheads.”

“I’ve been involved since about 1996 and I’ve always had a fairly free rein,” says Gareth. “That was when Dad started doing more with the Ulster Farmers Union.”

William served as president of the Ulster Farmers Union from 1998-2000 and was chairman of Copa-Coega [the voice of farmers and agri cooperatives in the EU] in 2000.

William Taylor and his son Gareth enjoy working together, with the support of both their wives. \ Claire Nash

Gareth enjoys getting advice from his dad; and in return, William says: “I am thrilled whenever Gareth rings me.”

“He rings me and says, ‘what do you think about this?’ I could be in Dublin or Galway and he will ring me to ask for my opinion. So, in many ways, I’m very blessed and thankful,” says William.

“And the children also do their bit on a Saturday or Sunday morning,” smiles Gareth. “They’ve always had to, I suppose.”

We leave William and Gareth to get on with their jobs on the farm, with a tub of original vanilla bean ice cream to enjoy on the way home.

See glastryfarm.com

It’s a bright Monday morning on the Ards Peninsula as the sun shines down on the rolling rural landscape. Farmland birds skirt between bushy hedgerows and hundreds of happy heads look out at us, waiting for milking time at Glastry Farm.

The dairy farm in Kircubbin, Co Down has been the home of the Taylor family for 150 years. Glastry has been milking cows since 1856, and William Taylor and his son, Gareth are now the fifth and sixth generation working the farm, which is approximately 260ac owned and a further 150ac leased.

William and his wife Cynthia manage the ice cream production side of the business, and Gareth and his wife Liz look after the dairy farm, with its 400-strong herd. It’s a full family affair with Gareth’s three children, Tom, Isla and Amy, also mucking out.

Irish Country Living arrived up to Glastry Farm shortly after Balmoral Show. The team scooped a mighty 1,200 litres of ice cream at Northern Ireland’s largest agricultural show.

It was nearly 20 years ago, in 2007, when the farm diversified into the production of ice cream. “I was standing outside the farm about this time of year and a tanker driver pulled up,” says William. “I asked him, well how’s things? The usual chit chat. He said: very busy, very busy. I’ve got about three loads [of milk] to get rid of today.

“When he was driving down the road, I started to think. It takes two and a half years bringing heifer calves to the stage of actually milking, all the work and planning and preparation and legislation that surrounds producing a fresh product. Then somebody tells me he’s taking it away to get rid of it and what he meant was he was taking it to the processing plant to make powder, butter or something or other.

“That got me thinking. So I took a Nuffield scholarship to investigate the opportunities for agri-food. It involved me visiting parts of what was then the new Europe, like Slovakia as well as countries such as France and Germany, to look at cooperation and farm diversification. I came home greatly impressed.

“I had visited a farm that turned potatoes into vodka and we were on a 3ha farm in Slovenia that produced a range of wines from their vineyard on a hill that I could hardly walk up.”

When William came home, he did a product development programme in conjunction with the Food Technology Centre at Cookstown and a market research survey with the support of Ulster University. Convinced the farm had to develop for the future and get better value from their product, they expanded their milk production unit and launched their ice cream in 2007.

Glastry make about 16 different flavours of ice cream. Pictured is their Chocolate & Mallow. \ Claire Nash

From milk to ice cream

Fresh milk is transferred from the milking parlour to the processing facility on the farm, where it is handmade into about 16 different flavours of ice cream, including a suite of seven sorbets.

William and his team show Irish Country Living around the ice cream plant.

And we’re in luck.

The team are making two sorbets – Pear Pear and Açaí Berry. The latter is a new flavour. We are shown the pasteuriser, continuous freezer, and production room where all the ingredients are weighed out and measured up.

“We try to get our ingredients from local suppliers. Our Irish whiskey flavour uses Dunville’s Irish whiskey. It’s local. The yellowman for our Yellowman Honeycomb comes from Aunt Sandras in Belfast and it has a beautiful chewy toffee flavour,” says William.

“We have plenty of ideas for flavour combinations,” William goes on. “Last autumn, we launched a delicious cherry flavour [Cherry Blossom] and we do a Toffee Apple ice cream for Halloween.”

The weekly ice cream production operates like a well-oiled machine, with about 90 5l tubs of ice cream made in one run. The sorbet is made on different days to the ice cream to avoid cross-contamination. It is also a nut-free site: “we made a decision about seven years ago that we would go nut-free, and it’s actually proved to be commercially attractive for us,” says William.

The introduction of sorbets to the range has also been another strong business decision for Glastry. “Sorbet has moved on from being a palate-cleanser at the start of a meal to actually being a dessert,” says William. “They’re sort of like a lower sugar, lower fat and healthier alternative. It’s good for people who can’t have dairy and they have the highest fruit content currently on the market.”

Glastry’s Raspberry Ruffle and Mango and Passionfruit Sorbet both received a One Star Great Taste Award in 2024. The Mango and Passionfruit Sorbet also received a bronze award in the Irish Quality Food and Drink Awards 2024 and a silver award in the Blas na hÉireann Irish Food Awards 2024.

Wagyu beef

On the other side of the business, Gareth tells us that: “the herd of 370 cows have produced a herd average to end of April 2025 of 841 kgs/cow of fat and protein.” He adds that Glastry has also diversified into Wagyu beef, rearing between 40 and 60 this year.

“We use sexed semen on around 50% of our dairy herd, mating them to pure Holstein-Friesian for heifer replacement.

The herd of 370 cows have produced a herd average to end of April 2025 of 841 kgs/cow of fat and protein. \ Claire Nash

The farm dairy has been completely self-contained for a generation. The other 50% of the herd is mated to Wagyu semen and we produce around 150 Wagyu offspring, which are kept on farm until they are six weeks old before moving to a specialist rearer who takes them through to finish,” says Gareth.

As we walk around the farm, William points out the present he bought for each of his three grandchildren six years ago: a pedigree Jersey heifer.

He shows Irish Country Living their current offspring for the 2025 season. They’re a beautiful caramel colour and William’s grandchildren adore them. “They’re a good pet, aren’t they?” he says, laughing. “They’re multiplying quite rapidly and we’re guaranteed heifers. It’s great.”

When asked what is it like running a family business, father and son have no complaints.

“Running a family business is a double-edged sword,” says William. “You can get almost instant decisions at breakfast time for either a day’s work or the following week’s work. Equally, I think because of the generation gap, there’s differences of opinion about what’s important for the family business. I’m very fortunate that we don’t fall out. We’re not at loggerheads.”

“I’ve been involved since about 1996 and I’ve always had a fairly free rein,” says Gareth. “That was when Dad started doing more with the Ulster Farmers Union.”

William served as president of the Ulster Farmers Union from 1998-2000 and was chairman of Copa-Coega [the voice of farmers and agri cooperatives in the EU] in 2000.

William Taylor and his son Gareth enjoy working together, with the support of both their wives. \ Claire Nash

Gareth enjoys getting advice from his dad; and in return, William says: “I am thrilled whenever Gareth rings me.”

“He rings me and says, ‘what do you think about this?’ I could be in Dublin or Galway and he will ring me to ask for my opinion. So, in many ways, I’m very blessed and thankful,” says William.

“And the children also do their bit on a Saturday or Sunday morning,” smiles Gareth. “They’ve always had to, I suppose.”

We leave William and Gareth to get on with their jobs on the farm, with a tub of original vanilla bean ice cream to enjoy on the way home.

See glastryfarm.com

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: