Given the cost of fertiliser, coupled with the increasingly stringent regulations, even and accurate spreading is becoming increasingly important, not only to save money but in order to get the most efficient use out of the quantity spread.

Now is the time

Whether you are following cows with fertiliser or preparing to spread meadows ahead of second cut, now is a good opportunity to give the spreader a quick lookover from a maintenance aspect and carry out a calibration test as performance may have slipped since earlier in the spring.

It’s unlikely that there has been much change since the start of the season, but it’s no harm to have a glance around the machine mid-season.

Inspect the frame, hopper and spreading mechanism for any signs of wear or fatigue, such as cracks or severe corrosion that may affect its overall load carrying ability. Similarly, the hopper should be closing and opening fully.

Worn linkages or other regulator components will result in an inaccurate and uneven application.

Vanes that have a rough or wrinkled surface and leading edge that isn’t straight will need to be replaced.

On older machines, assess gearbox condition by shaking the disc vertically. Excess movement will indicate bearing failure.

Check the condition of gearbox bearings by shaking the discs vertically. Ideally, there should be no bearing wobble.

The agitators in the hopper should be checked over and be in good working order.

Check that any other parts which should move, are moving freely.

All grease points should get grease before mounting on the tractor. If there is a headland management system fitted, make sure it is engaging and disengaging fully.

The first thing to do before attaching the spreader is to ensure both drop arms on the tractor are the same length and that rear tyre pressures are equal.

An unlevel spreader will affect spread pattern.

Once mounted on the tractor, ensure that the spreader is mounted at the centre of the tractor’s track width and that both stabilisers are tight, allowing no lateral movement.

Once this is complete, raise the spreader to the correct working height.

The general rule is to have a distance of 75cm from the top of the crop to the spreading mechanism. Next, adjust the toplink to the angle advised by either the spread chart or manufacturer.

The spreader should be securely fastened at the centre of the tractor’s track width using the stabilisers.

A disc machine has two main areas of adjustment – fertiliser flow rate and disc/vane settings. A wagtail has just one area to adjust – flow rate.

The steps involved in setting the desired flow rate on both machine types is similar.

Flow rate is adjusted by moving the regulator. Obviously, one setting for a desired application rate for a particular product will vary for the next as the flow rates of each will vary depending on characteristics of the sample (shape, size and brand). What’s more, no two samples are the same.

Understanding the correct flow rate is essential if a correct application rate (kg/ha) is to be achieved.

Setting the regulator only ensures that the correct amount is coming out of the machine.

Further adjustments may be needed to ensure fertiliser is being spread evenly. These adjustments will vary between brand sand models, so refer to calibration settings for your specific machine.

Disc type

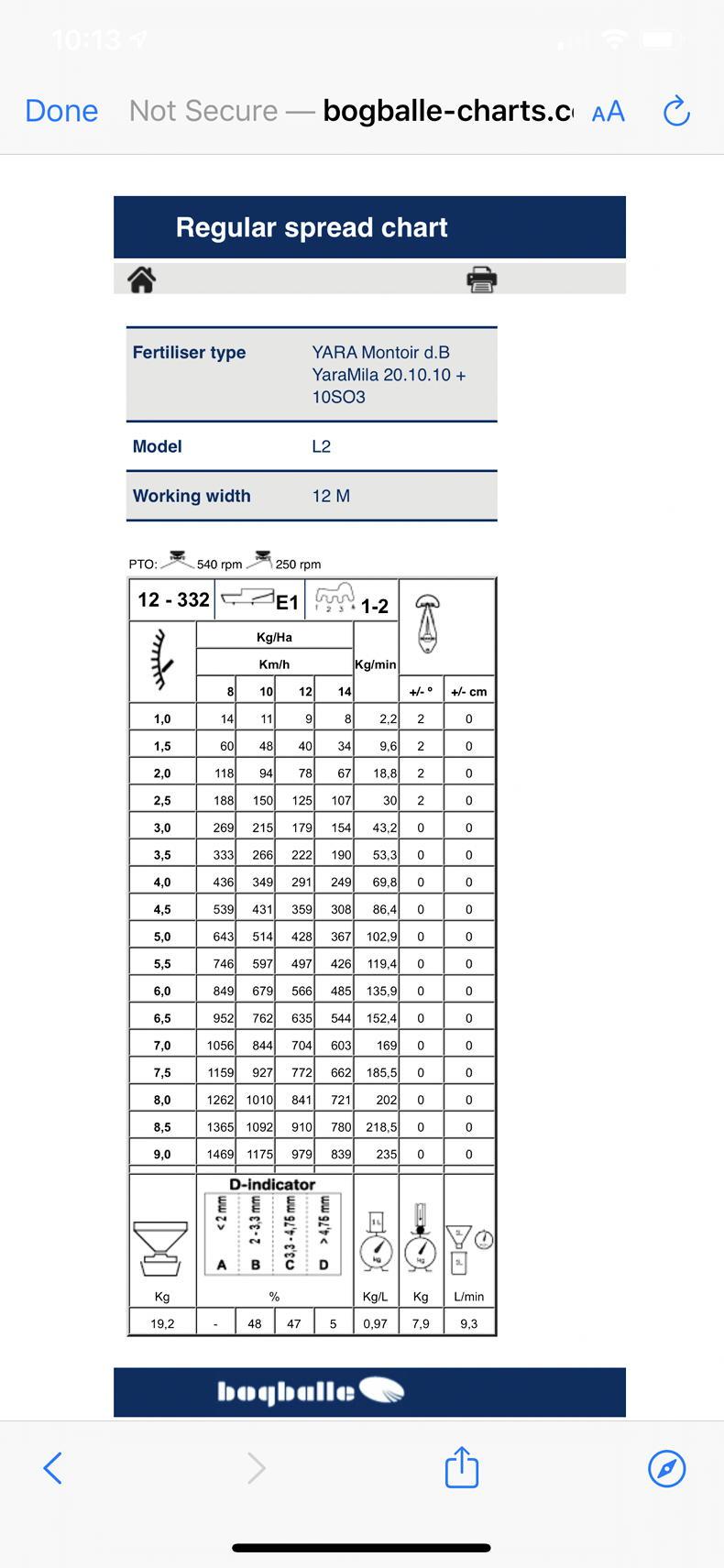

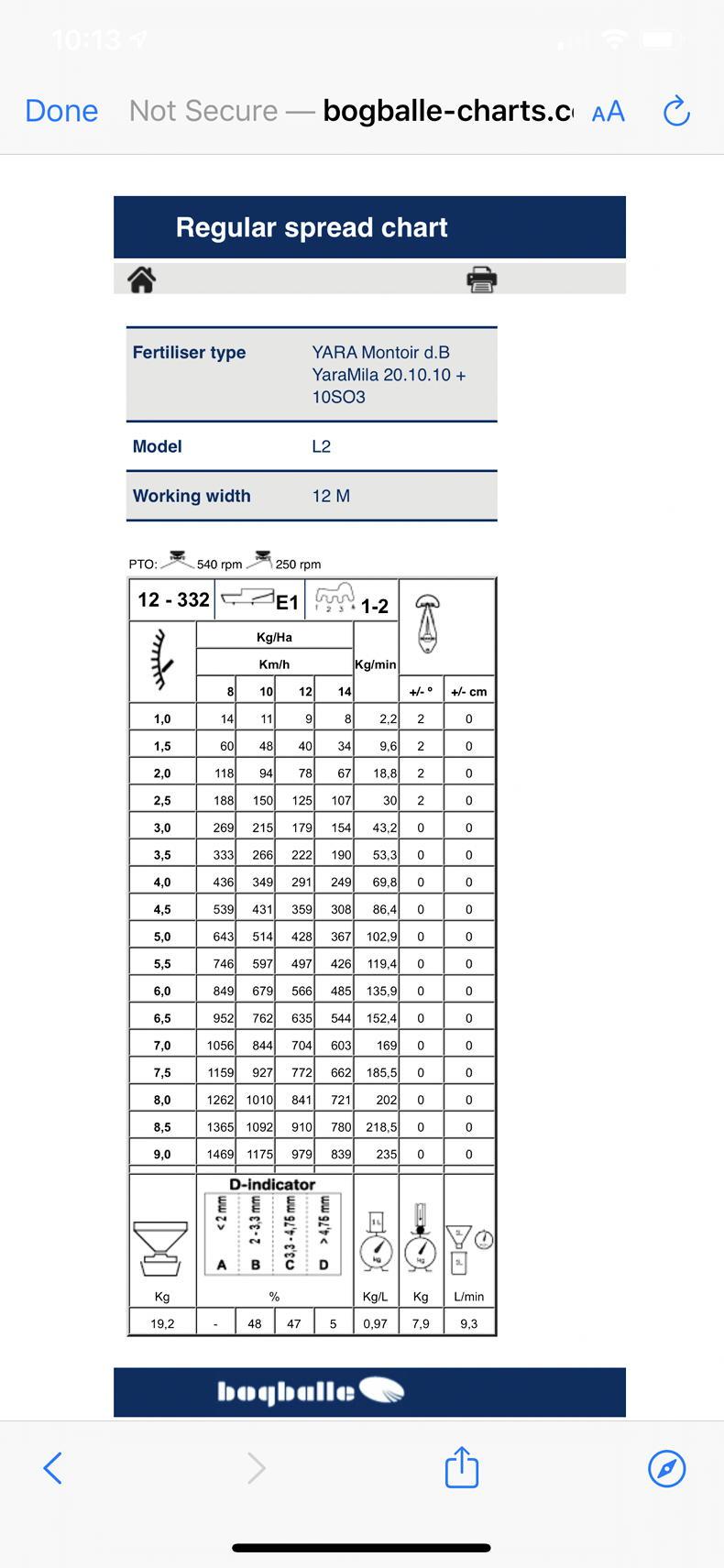

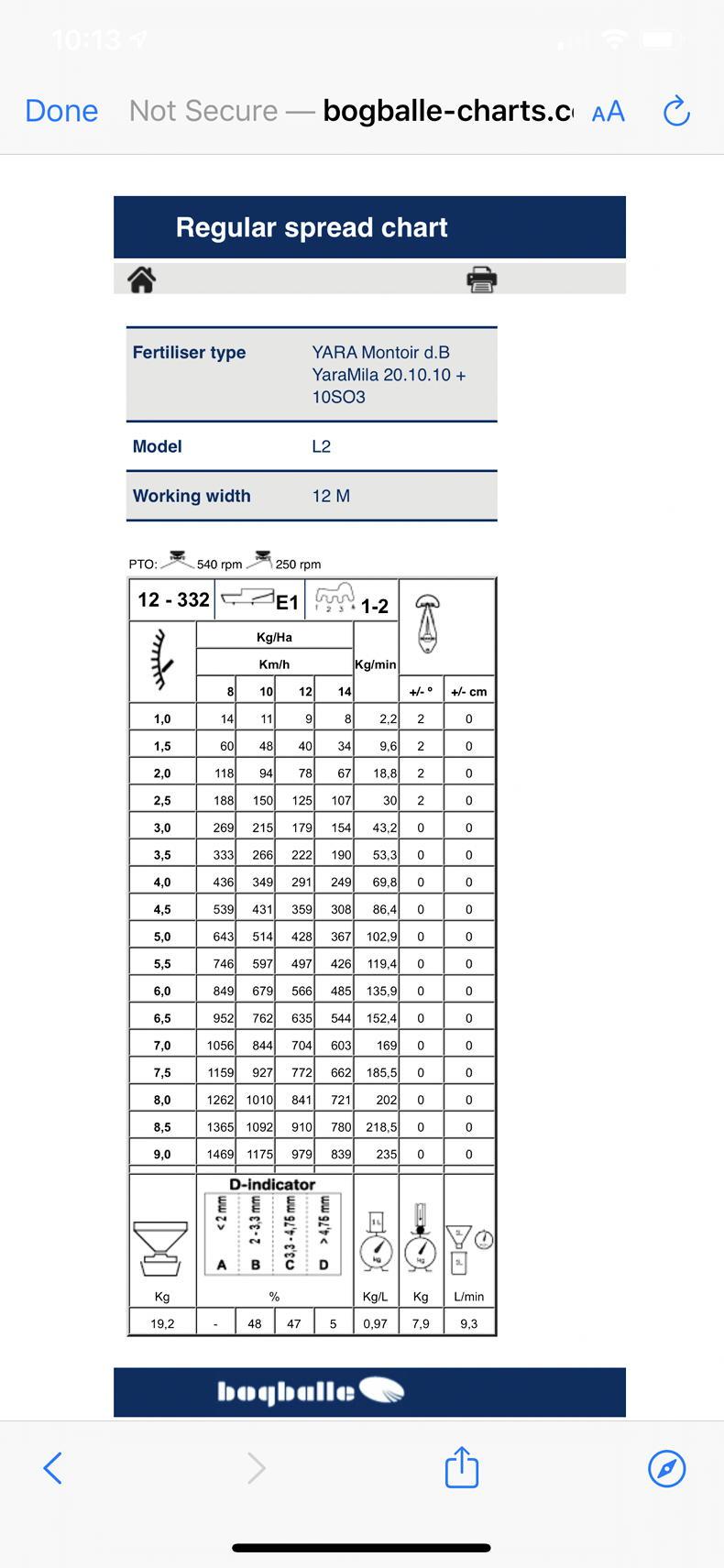

To set the spreader to suit a particular product, bout width and/or application rate, the following adjustments may need to be made as per the spread chart – vane type and position, fertiliser drop point, toplink angle and maybe even disc size.

These adjustments vary from brand to brand so refer to the specific manufacturer’s settings and spread charts (in the spreader manual or settings book).

Most manufacturers have smartphone apps that show spread charts and have calculators that allow you input information such as fertiliser type, application rate, forward speed and spreading width and then display the machine settings to achieve this.

All major manufacturers have a huge selection of fertiliser types and brands already tested in their test halls.

The spread chart will also indicate the accurate kg/min for each particular fertiliser for a machine. However, fertiliser will vary over time and calibrating the flow rate is the only way to make sure the output setting is fully correct.

The correct flow rate is essential if a correct application rate (kg/ha) is to be achieved.

To do this, shut off one side of the spreader, remove the disc on the other side and fit a calibration container or a bucket. The spreader should be run for thirty seconds while the container gathers the fertiliser.

The PTO should be running during the calibration as the agitator at the bottom of the hopper needs to be moving to ensure an even and steady flow of fertiliser.

Most manufacturers have calibration kits to determine the flow rate of different product types.

After thirty seconds, calculate the amount collected and multiply by four. The container’s weight should match the kg/min rate as displayed by the app or spread chart. If the two figures don’t match, some fine-tuning may be required.

On older machines, assess gearbox condition by shaking the disc vertically. Excess movement will indicate bearing failure.

Wagtail

Wagtail spreaders require no further setting up once mounted correctly and the flow rate has been established. This is done using the regulator, and again depends on the working width (m), application rate (kg/ha), forward speed (km/h) and type of fertiliser being applied.

The regulator on a wagtail spreader tends to differ from the regulator on a disc machine.

Again, most manufacturers have apps that allow you input these variables along with the fertiliser type. The app will provide you with a setting or spread chart to suit the fertiliser being used.

Once again, the spreader’s flow rate should be calibrated to ensure it spreads what it is set to.

Once the machine is set up, it’s down to the operator to drive accurately, ensuring PTO and forward speed is correct and the correct bout width is maintained.

To check the spread pattern of the fertiliser across the bout width, a tray test can be carried out. This involves laying out trays evenly across the working width and making a pass spreading fertiliser over the trays.

Performing a tray test will indicate the evenness of fertiliser distribution.

The material in each tray is then put into small tubes so that the balance of spread pattern can be assessed. This is important to ensure accurate application and should be carried out at least once a season for each fertiliser type.

All major manufacturers will have calibration and spread chart apps.

Given the cost of fertiliser, coupled with the increasingly stringent regulations, even and accurate spreading is becoming increasingly important, not only to save money but in order to get the most efficient use out of the quantity spread.

Now is the time

Whether you are following cows with fertiliser or preparing to spread meadows ahead of second cut, now is a good opportunity to give the spreader a quick lookover from a maintenance aspect and carry out a calibration test as performance may have slipped since earlier in the spring.

It’s unlikely that there has been much change since the start of the season, but it’s no harm to have a glance around the machine mid-season.

Inspect the frame, hopper and spreading mechanism for any signs of wear or fatigue, such as cracks or severe corrosion that may affect its overall load carrying ability. Similarly, the hopper should be closing and opening fully.

Worn linkages or other regulator components will result in an inaccurate and uneven application.

Vanes that have a rough or wrinkled surface and leading edge that isn’t straight will need to be replaced.

On older machines, assess gearbox condition by shaking the disc vertically. Excess movement will indicate bearing failure.

Check the condition of gearbox bearings by shaking the discs vertically. Ideally, there should be no bearing wobble.

The agitators in the hopper should be checked over and be in good working order.

Check that any other parts which should move, are moving freely.

All grease points should get grease before mounting on the tractor. If there is a headland management system fitted, make sure it is engaging and disengaging fully.

The first thing to do before attaching the spreader is to ensure both drop arms on the tractor are the same length and that rear tyre pressures are equal.

An unlevel spreader will affect spread pattern.

Once mounted on the tractor, ensure that the spreader is mounted at the centre of the tractor’s track width and that both stabilisers are tight, allowing no lateral movement.

Once this is complete, raise the spreader to the correct working height.

The general rule is to have a distance of 75cm from the top of the crop to the spreading mechanism. Next, adjust the toplink to the angle advised by either the spread chart or manufacturer.

The spreader should be securely fastened at the centre of the tractor’s track width using the stabilisers.

A disc machine has two main areas of adjustment – fertiliser flow rate and disc/vane settings. A wagtail has just one area to adjust – flow rate.

The steps involved in setting the desired flow rate on both machine types is similar.

Flow rate is adjusted by moving the regulator. Obviously, one setting for a desired application rate for a particular product will vary for the next as the flow rates of each will vary depending on characteristics of the sample (shape, size and brand). What’s more, no two samples are the same.

Understanding the correct flow rate is essential if a correct application rate (kg/ha) is to be achieved.

Setting the regulator only ensures that the correct amount is coming out of the machine.

Further adjustments may be needed to ensure fertiliser is being spread evenly. These adjustments will vary between brand sand models, so refer to calibration settings for your specific machine.

Disc type

To set the spreader to suit a particular product, bout width and/or application rate, the following adjustments may need to be made as per the spread chart – vane type and position, fertiliser drop point, toplink angle and maybe even disc size.

These adjustments vary from brand to brand so refer to the specific manufacturer’s settings and spread charts (in the spreader manual or settings book).

Most manufacturers have smartphone apps that show spread charts and have calculators that allow you input information such as fertiliser type, application rate, forward speed and spreading width and then display the machine settings to achieve this.

All major manufacturers have a huge selection of fertiliser types and brands already tested in their test halls.

The spread chart will also indicate the accurate kg/min for each particular fertiliser for a machine. However, fertiliser will vary over time and calibrating the flow rate is the only way to make sure the output setting is fully correct.

The correct flow rate is essential if a correct application rate (kg/ha) is to be achieved.

To do this, shut off one side of the spreader, remove the disc on the other side and fit a calibration container or a bucket. The spreader should be run for thirty seconds while the container gathers the fertiliser.

The PTO should be running during the calibration as the agitator at the bottom of the hopper needs to be moving to ensure an even and steady flow of fertiliser.

Most manufacturers have calibration kits to determine the flow rate of different product types.

After thirty seconds, calculate the amount collected and multiply by four. The container’s weight should match the kg/min rate as displayed by the app or spread chart. If the two figures don’t match, some fine-tuning may be required.

On older machines, assess gearbox condition by shaking the disc vertically. Excess movement will indicate bearing failure.

Wagtail

Wagtail spreaders require no further setting up once mounted correctly and the flow rate has been established. This is done using the regulator, and again depends on the working width (m), application rate (kg/ha), forward speed (km/h) and type of fertiliser being applied.

The regulator on a wagtail spreader tends to differ from the regulator on a disc machine.

Again, most manufacturers have apps that allow you input these variables along with the fertiliser type. The app will provide you with a setting or spread chart to suit the fertiliser being used.

Once again, the spreader’s flow rate should be calibrated to ensure it spreads what it is set to.

Once the machine is set up, it’s down to the operator to drive accurately, ensuring PTO and forward speed is correct and the correct bout width is maintained.

To check the spread pattern of the fertiliser across the bout width, a tray test can be carried out. This involves laying out trays evenly across the working width and making a pass spreading fertiliser over the trays.

Performing a tray test will indicate the evenness of fertiliser distribution.

The material in each tray is then put into small tubes so that the balance of spread pattern can be assessed. This is important to ensure accurate application and should be carried out at least once a season for each fertiliser type.

All major manufacturers will have calibration and spread chart apps.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: