Sowing maize in the open without the use of plastic has been gaining popularity in certain areas of the country recently. However, some farmers and contractors have been doing this for years. Based three miles from Cahir in Co Tipperary, Philip Kiely, and his son Bill run an agricultural contracting business, and farm alongside. Having bought their first maize drill in 1999, the family originally sowed maize in the open, before plastic became the common practice, but always offered their clients both systems, and continue to do so today.

Starting off with a four-row Accord planter, the Kielys progressed to a six-row Gaspardo unit, which was later upgraded to a six-row Amazone planter. In these same years, the Kielys purchased a new four-row, Limerick-built Samco maize drill, with this later having been upgraded to a new six-row Samco drill in recent years.

“As maize planting intensified, the agronomy and the system around growing it and maximising its yield got better over the years. The use of plastic was like an insurance policy, and it helped increase yields. However, not all of our farmer customers wanted to go this route, so we continued to offer both services – sowing maize in the open and under plastic. This continues to be the case today. We see some years, some customers might swap sowing methods from year to year, depending on the land and the weather conditions. Today, we sow around 65% in the open and the remaining 35% under plastic,” explained Philip.

In 2023, the Kielys opted to upgrade their six-row Amazone planter and decided to purchase a new Lemken Azurit 9 planter with a Solitair 8 front fertiliser hopper. The decision to go with Lemken was largely based on the machine’s seed placement and its DeltaRow seeding system. After happily running this machine for two seasons, an ex-demo Azurit 10, eight-row machine became available. Although the Kielys hadn’t planned to upgrade the machine so soon, they felt that moving to a larger output machine, with the same seeding technology, would be a good move.

'We are very happy with the drill and our customers are very happy with their crops, so it’s doing everything we have asked of it,' explained Philip.

\ Odhran Ducie

DeltaRow is Lemken’s precision seeding concept, which comprises of two staggered twin rows arranged at a distance of 12.5cm apart.

\ Odhran Ducie

A metering auger feeds the seeds from the hopper into the air stream and then on to the seed metering units. \ Odhran Ducie

Lemken Azurit

The Azurit is Lemken’s precision seed drill range. The Azurit 10 precision seed drill is available with four to 12 rows and various row spacings. Once the seed furrow has been cleared, fertiliser is applied centrally underneath the DeltaRow via a double disc coulter. The Azurit can be used by itself as a standalone drill, or can be combined with various other implements in the Lemken range, such as the Solitair 25 trailed power harrow and drill combination, with fertiliser held in the tank of the Solitair 25 pneumatic seed drill, the Compact-Solitair 9, where fertiliser is also held in the drill combination tank and released by the metering system, or with the Solitair 12 SW seed trailer. The tramline mechanism of the Azurit 10 provides the option of applying farm manure to the crop.

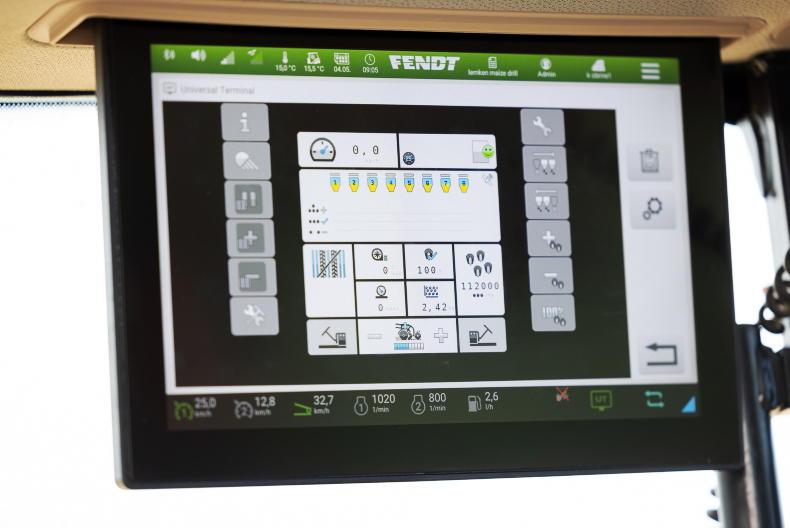

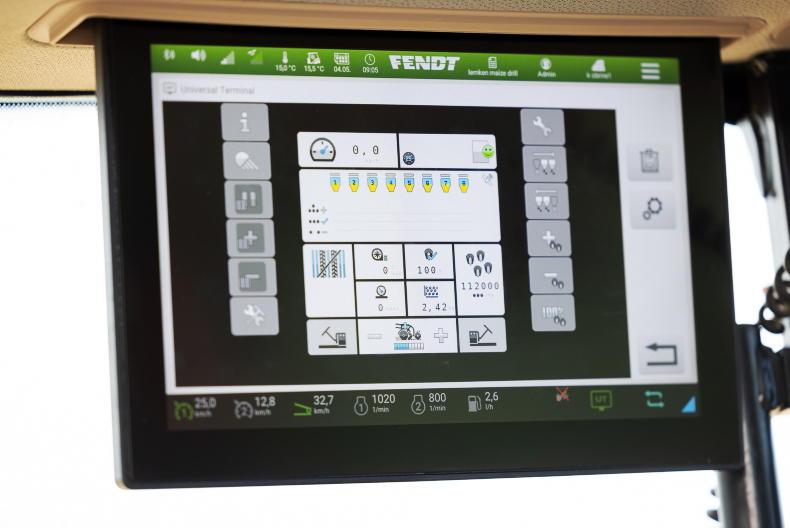

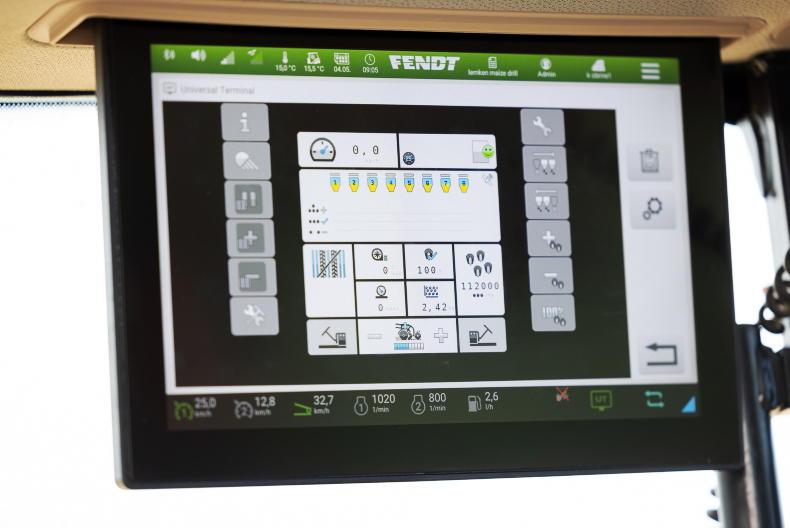

The Kielys run the drill on a Fendt 724, and then run it through the tractors own IsoBus screen. \ Odhran Ducie

Bill Kiely (middle), with his son Philip and father, Philip. \ Odhran Ducie

Two double-disc coulters place the seeds on the reconsolidated seed horizon in a DeltaRow arrangement. \ Odhran Ducie

DeltaRow seeding concept

DeltaRow is Lemken’s precision seeding concept, which comprises of two staggered twin rows arranged at a distance of 12.5cm apart. Lemken claims it offers precise placement in a triangular seeding pattern, which is ensured by synchronising the twin rows. The manufacturer claims that compared to single rows, DeltaRows offer 70% more surface area and therefore more water, nutrients and light for each plant. The fertiliser band is placed in the sub-root area inside the DeltaRow. It says this allows a symmetrical design of the seeding unit.

“The accuracy of the DeltaRow seeding concept is second to none. It places the seeds exactly in the right position, every time. It’s a seriously accurate system,” said Philip.

The Kielys run the Azurit 10 in tandem with the Solitair 8 front-mounted fertiliser hopper, which holds 1.5t of fertiliser. \ Odhran Ducie

'Today, we sow around 65% in the open, and the remaining 35% under plastic,' explained Philip. \ Odhran Ducie

The Azurit 10 precision seed drill is available with four to 12 rows and various row spacings.\ Odhran Ducie

Workings of the drill

Lemken says its drill carries out five functions. Firstly, the row cleaners remove stones, clods and residue from the seed furrows. Their height can be adjusted easily via a perforated grid, or they can be removed altogether if required. Next up, the fertiliser coulter, which can place up to 250kg coulter pressure, places a band of fertiliser underneath the DeltaRow centrally between the two twin rows of maize. The Kielys run the Azurit 10 in tandem with the Solitair 8 front-mounted fertiliser hopper, which holds 1.5t of fertiliser.

The third function is reconsolidation. Lemken says the trapezoid furrow press element covers the fertiliser band and at the same time ensures that the seed horizon is reconsolidated. After this, two double disc coulters place the seeds on the reconsolidated seed horizon in a DeltaRow arrangement. Lemken says that once seeds have exited the seeding shafts, guide wheels ensure that they remain precisely at the desired position in the seed horizon. Finally, the furrow closers ensure that the seeds are covered with soil and pressed into place.

Lemken claims DeltaRow offers precise placement in a triangular seeding pattern, which is ensured by synchronising the twin rows.

Odhran Ducie

Lemken claims the Azurit 10 delivers excellent seed metering quality at high working speeds, thanks to the low circumferential speed of the perforated discs. . \ Odhran Ducie

Two optical sensors monitor the accuracy of seed metering. \ Odhran Ducie

Seed metering

The Azurit 10 is fitted with a central 600-litre seed hopper, which is easily accessible. Each metering unit only holds a small number of seeds. The continuous, automatic supply of seeds from the central hopper is sensor-controlled. A metering auger feeds the seeds from the hopper into the air stream and then on to the seed metering units. Lemken claims the Azurit 10 delivers excellent seed metering quality at high working speeds, thanks to the low circumferential speed of the perforated discs. The trapezoid furrow press pre-compacts the rows and therefore ensures a steady position of the seeding units.

Lemken explains that positive pressure in the system conveys seeds from the metering unit to the seed row via a seeding shaft. Two optical sensors monitor the accuracy of seed metering. Once seeds have exited the seeding shaft, a guide wheel ensures that they remain in place. The seeds are metered by two perforated discs arranged offset to each other. The fixed connection between the two seed discs ensures synchronisation within the DeltaRow. Each metering unit is driven by a separate electric motor. The planter features individual row by row shut off, ensuring minimal waste.

Seed residue in the tank can be emptied centrally if need be via a start button directly on the seed hopper. Meanwhile, seeds in the metering unit can be removed by opening a discharge flap.

Once seeds have exited the seeding shaft, a guide wheel ensures that they remain in place. \ Odhran Ducie

The seeds are metered by two perforated discs arranged offset to each other. \ Odhran Ducie

Controls

Users have the option of operating the planter through the tractor’s own IsoBus screen, through a CCI-1200 IsoBus terminal or through any universal IsoBus terminal. The Kielys run the drill on a Fendt 724 and then run it through the tractor’s own IsoBus screen.

Lemken says that when using the planter’s layout manager, the user interfaces can be freely configured and saved for up to four driver profiles. MegaSeed is Lemken’s IsoBus-based control concept for the Azurit 10 precision seed drill. The MultiBoom feature supports automatic, separate section control for fertiliser and seeds to prevent overlaps. The manufacturer says it’s also possible to work through two application maps in parallel, so that seeds and fertiliser are only applied where they can be used efficiently. The planter’s information menu gives access to various diagnostic options. Lemken explains that in the event of a fault, the new diagnostic system guides the driver directly to the source of the fault and assists them in rectifying it.

The Azurit 10 is fitted with a central 600-litre seed hopper. \ Odhran Ducie

Microgranule unit

The Azurit 10 can be equipped with an electrically driven MicroHub microgranule unit, which comes with a 200l central tank. The air flow of the Azurit transfers the microgranules from the tank to the distributor via a metering device. The microgranules are distributed across up to eight rows. Next, they are fed to the respective DeltaRows via Y-sections, and are then placed together with the seeds. Lemken says that a stainless-steel metering shaft is fitted as standard and delivers application rates between 5kg to 40kg per hectare at forward speeds of up to 15km/h. A fill level sensor shows the operator how much granulate is still in the tank.

Verdict

“We are hugely impressed with the planter – it does what it says on the tin. It’s extremely accurate, and in the right conditions is well capable of getting through a huge amount of work. Where conditions allow, we regularly sow at 12km/h, allowing an output of up to 15-20ac/hour in good-sized fields. The DeltaRow seeding concept places the seed in the right place, every time. The accuracy of seed placement is phenomenal. In addition, the accuracy of the seed metering system is top notch – it’s extremely accurate. We are very happy with the drill and the backup service from TFM, and our customers are very happy with their crops, so it’s doing everything we have asked of it,” explained Philip.

Sowing maize in the open without the use of plastic has been gaining popularity in certain areas of the country recently. However, some farmers and contractors have been doing this for years. Based three miles from Cahir in Co Tipperary, Philip Kiely, and his son Bill run an agricultural contracting business, and farm alongside. Having bought their first maize drill in 1999, the family originally sowed maize in the open, before plastic became the common practice, but always offered their clients both systems, and continue to do so today.

Starting off with a four-row Accord planter, the Kielys progressed to a six-row Gaspardo unit, which was later upgraded to a six-row Amazone planter. In these same years, the Kielys purchased a new four-row, Limerick-built Samco maize drill, with this later having been upgraded to a new six-row Samco drill in recent years.

“As maize planting intensified, the agronomy and the system around growing it and maximising its yield got better over the years. The use of plastic was like an insurance policy, and it helped increase yields. However, not all of our farmer customers wanted to go this route, so we continued to offer both services – sowing maize in the open and under plastic. This continues to be the case today. We see some years, some customers might swap sowing methods from year to year, depending on the land and the weather conditions. Today, we sow around 65% in the open and the remaining 35% under plastic,” explained Philip.

In 2023, the Kielys opted to upgrade their six-row Amazone planter and decided to purchase a new Lemken Azurit 9 planter with a Solitair 8 front fertiliser hopper. The decision to go with Lemken was largely based on the machine’s seed placement and its DeltaRow seeding system. After happily running this machine for two seasons, an ex-demo Azurit 10, eight-row machine became available. Although the Kielys hadn’t planned to upgrade the machine so soon, they felt that moving to a larger output machine, with the same seeding technology, would be a good move.

'We are very happy with the drill and our customers are very happy with their crops, so it’s doing everything we have asked of it,' explained Philip.

\ Odhran Ducie

DeltaRow is Lemken’s precision seeding concept, which comprises of two staggered twin rows arranged at a distance of 12.5cm apart.

\ Odhran Ducie

A metering auger feeds the seeds from the hopper into the air stream and then on to the seed metering units. \ Odhran Ducie

Lemken Azurit

The Azurit is Lemken’s precision seed drill range. The Azurit 10 precision seed drill is available with four to 12 rows and various row spacings. Once the seed furrow has been cleared, fertiliser is applied centrally underneath the DeltaRow via a double disc coulter. The Azurit can be used by itself as a standalone drill, or can be combined with various other implements in the Lemken range, such as the Solitair 25 trailed power harrow and drill combination, with fertiliser held in the tank of the Solitair 25 pneumatic seed drill, the Compact-Solitair 9, where fertiliser is also held in the drill combination tank and released by the metering system, or with the Solitair 12 SW seed trailer. The tramline mechanism of the Azurit 10 provides the option of applying farm manure to the crop.

The Kielys run the drill on a Fendt 724, and then run it through the tractors own IsoBus screen. \ Odhran Ducie

Bill Kiely (middle), with his son Philip and father, Philip. \ Odhran Ducie

Two double-disc coulters place the seeds on the reconsolidated seed horizon in a DeltaRow arrangement. \ Odhran Ducie

DeltaRow seeding concept

DeltaRow is Lemken’s precision seeding concept, which comprises of two staggered twin rows arranged at a distance of 12.5cm apart. Lemken claims it offers precise placement in a triangular seeding pattern, which is ensured by synchronising the twin rows. The manufacturer claims that compared to single rows, DeltaRows offer 70% more surface area and therefore more water, nutrients and light for each plant. The fertiliser band is placed in the sub-root area inside the DeltaRow. It says this allows a symmetrical design of the seeding unit.

“The accuracy of the DeltaRow seeding concept is second to none. It places the seeds exactly in the right position, every time. It’s a seriously accurate system,” said Philip.

The Kielys run the Azurit 10 in tandem with the Solitair 8 front-mounted fertiliser hopper, which holds 1.5t of fertiliser. \ Odhran Ducie

'Today, we sow around 65% in the open, and the remaining 35% under plastic,' explained Philip. \ Odhran Ducie

The Azurit 10 precision seed drill is available with four to 12 rows and various row spacings.\ Odhran Ducie

Workings of the drill

Lemken says its drill carries out five functions. Firstly, the row cleaners remove stones, clods and residue from the seed furrows. Their height can be adjusted easily via a perforated grid, or they can be removed altogether if required. Next up, the fertiliser coulter, which can place up to 250kg coulter pressure, places a band of fertiliser underneath the DeltaRow centrally between the two twin rows of maize. The Kielys run the Azurit 10 in tandem with the Solitair 8 front-mounted fertiliser hopper, which holds 1.5t of fertiliser.

The third function is reconsolidation. Lemken says the trapezoid furrow press element covers the fertiliser band and at the same time ensures that the seed horizon is reconsolidated. After this, two double disc coulters place the seeds on the reconsolidated seed horizon in a DeltaRow arrangement. Lemken says that once seeds have exited the seeding shafts, guide wheels ensure that they remain precisely at the desired position in the seed horizon. Finally, the furrow closers ensure that the seeds are covered with soil and pressed into place.

Lemken claims DeltaRow offers precise placement in a triangular seeding pattern, which is ensured by synchronising the twin rows.

Odhran Ducie

Lemken claims the Azurit 10 delivers excellent seed metering quality at high working speeds, thanks to the low circumferential speed of the perforated discs. . \ Odhran Ducie

Two optical sensors monitor the accuracy of seed metering. \ Odhran Ducie

Seed metering

The Azurit 10 is fitted with a central 600-litre seed hopper, which is easily accessible. Each metering unit only holds a small number of seeds. The continuous, automatic supply of seeds from the central hopper is sensor-controlled. A metering auger feeds the seeds from the hopper into the air stream and then on to the seed metering units. Lemken claims the Azurit 10 delivers excellent seed metering quality at high working speeds, thanks to the low circumferential speed of the perforated discs. The trapezoid furrow press pre-compacts the rows and therefore ensures a steady position of the seeding units.

Lemken explains that positive pressure in the system conveys seeds from the metering unit to the seed row via a seeding shaft. Two optical sensors monitor the accuracy of seed metering. Once seeds have exited the seeding shaft, a guide wheel ensures that they remain in place. The seeds are metered by two perforated discs arranged offset to each other. The fixed connection between the two seed discs ensures synchronisation within the DeltaRow. Each metering unit is driven by a separate electric motor. The planter features individual row by row shut off, ensuring minimal waste.

Seed residue in the tank can be emptied centrally if need be via a start button directly on the seed hopper. Meanwhile, seeds in the metering unit can be removed by opening a discharge flap.

Once seeds have exited the seeding shaft, a guide wheel ensures that they remain in place. \ Odhran Ducie

The seeds are metered by two perforated discs arranged offset to each other. \ Odhran Ducie

Controls

Users have the option of operating the planter through the tractor’s own IsoBus screen, through a CCI-1200 IsoBus terminal or through any universal IsoBus terminal. The Kielys run the drill on a Fendt 724 and then run it through the tractor’s own IsoBus screen.

Lemken says that when using the planter’s layout manager, the user interfaces can be freely configured and saved for up to four driver profiles. MegaSeed is Lemken’s IsoBus-based control concept for the Azurit 10 precision seed drill. The MultiBoom feature supports automatic, separate section control for fertiliser and seeds to prevent overlaps. The manufacturer says it’s also possible to work through two application maps in parallel, so that seeds and fertiliser are only applied where they can be used efficiently. The planter’s information menu gives access to various diagnostic options. Lemken explains that in the event of a fault, the new diagnostic system guides the driver directly to the source of the fault and assists them in rectifying it.

The Azurit 10 is fitted with a central 600-litre seed hopper. \ Odhran Ducie

Microgranule unit

The Azurit 10 can be equipped with an electrically driven MicroHub microgranule unit, which comes with a 200l central tank. The air flow of the Azurit transfers the microgranules from the tank to the distributor via a metering device. The microgranules are distributed across up to eight rows. Next, they are fed to the respective DeltaRows via Y-sections, and are then placed together with the seeds. Lemken says that a stainless-steel metering shaft is fitted as standard and delivers application rates between 5kg to 40kg per hectare at forward speeds of up to 15km/h. A fill level sensor shows the operator how much granulate is still in the tank.

Verdict

“We are hugely impressed with the planter – it does what it says on the tin. It’s extremely accurate, and in the right conditions is well capable of getting through a huge amount of work. Where conditions allow, we regularly sow at 12km/h, allowing an output of up to 15-20ac/hour in good-sized fields. The DeltaRow seeding concept places the seed in the right place, every time. The accuracy of seed placement is phenomenal. In addition, the accuracy of the seed metering system is top notch – it’s extremely accurate. We are very happy with the drill and the backup service from TFM, and our customers are very happy with their crops, so it’s doing everything we have asked of it,” explained Philip.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: