Taking on one underpass is a big enough investment and challenge, but doing two at the same time is an even bigger one. This didn’t seem to faze Kieran and Cathal O’Sullivan, who are farming in partnership in Goleen, Co Cork, where the father-and-son team are milking 180 cows along the Wild Atlantic Way.

Creating underpasses was on Cathal’s mind for many years, with the herd having to cross three separate roads to access the main grazing block. The fact that the farm is on the Wild Atlantic Way meant that tourist traffic, especially in the summer months, proved challenging when moving cows between paddock and parlour.

The decision was made to use two underpasses to alleviate this pressure; one crossing underneath a busy L road, with the other crossing a right of way used by two neighbouring farmers.

Planning was submitted in late 2023 with a TAMS application submitted in Aril 2024 and once some minor issues were resolved, permission was granted. In order to be able to install the two underpasses, the O’Sullivans had to take the corner of a field from their neighbour Maurice Downey, while a ditch also had to be taken down and replaced from neighbour Denis Hellen.

“We can’t thank them both enough, as without their co-operation, we wouldn’t have been able to complete the job,” said Kieran.

The roadway between the two underpasses was angled in such a way to avoid taking more of Maurice’s land than was necessary.

The O’Sullivans employed McCarthy Plant Hire, Skibbereen, as the main contractor as they had all the necessary certification and inusrance to complete the road closures and opening.

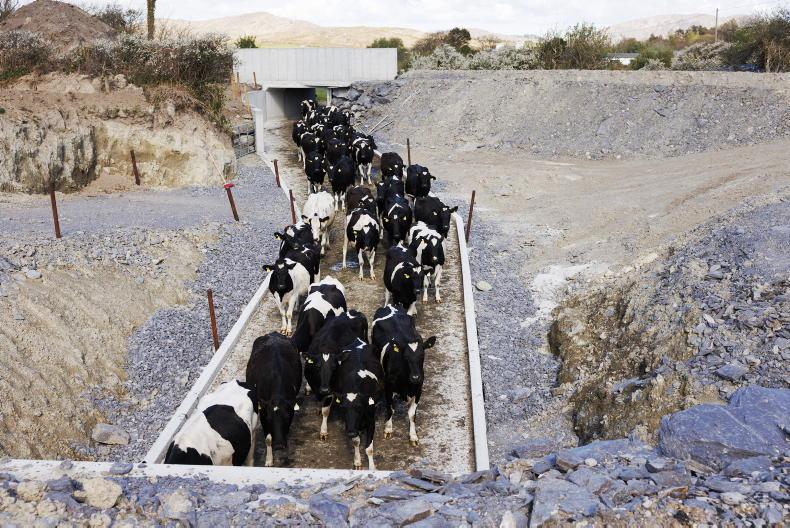

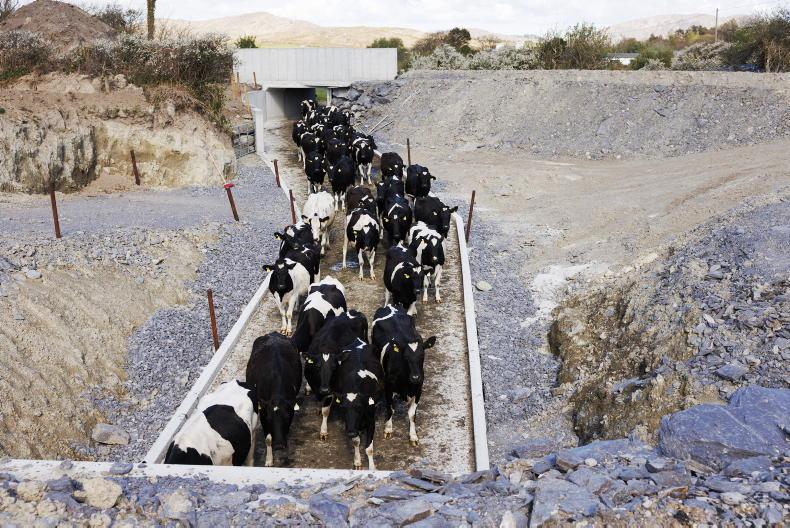

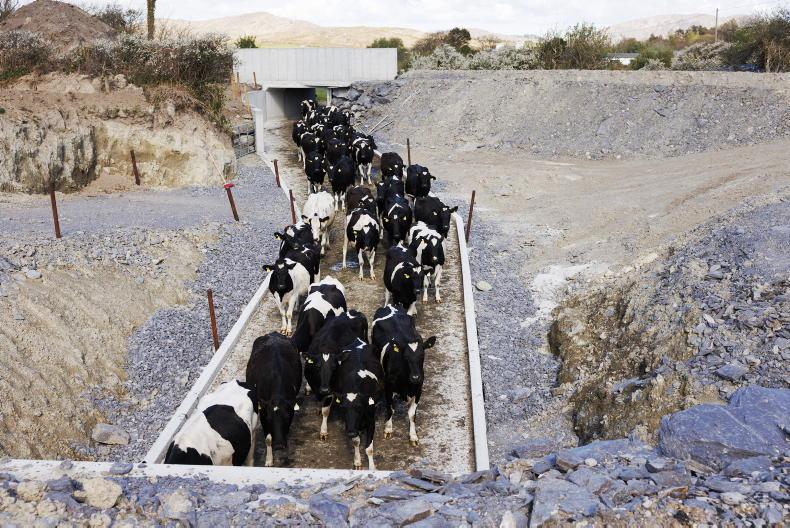

The cow was the main priority when it came to designing the underpasses, with sharp angles or ramps eliminated for cow flow. \ Donal O' Leary

Breaking ground

Ground was broken in early December by the O’Sullivans themselves, with the farm having two diggers for working on the holding. Both sides of the culverts were dug beforehand to reduce the workload on the contractor. Stone was dug from a nearby field and stockpiled for the side roads up from the main underpass, as well as for filling around the culverts after insertion.

Planning was key to the success of the job, with the O’Sullivans highly complementary of both Croom Concrete, which supplied the culverts, and McCarthy Plant Hire, which worked in tandem with each other around the road closure dates. The road was broken out on Monday 13 January, as per road closures, with the two roadways cut away and ready for culverts the following evening. Luckily, there were no services where the underpasses were being dug, which simplified the process. The 17 culverts were then hoisted in to position on Wednesday 15 January, with Croom Concrete and Kavanagh Cranes having both underpass culverts fitted by 5pm that evening and the crane sent off. The culverts were then sealed the next day, before the process of back-filling began.

Kieran and Cathal O' Sullivan, Goleen, Co Cork, with the new underpasses the built on the farm. \ Donal O' Leary

Finishing

To ensure that the road surface would be properly compacted, layers of stone fill and 8-0-4 material from Gloun Stone Ltd were laid down in 300mm layers and compacted using wacker plates and vibrating rollers. Ducting was placed during the back-filling to allow water or electricity to be carried through the culverts. The ground surrounding the culverts was good, which meant very little subsidence occurred anyway. A week after the culverts were laid, the road was tarred and reopened on Thursday 20 January, with the road having to be shut for just 10 days in total.

“Neighbours were very good, and didn’t mind using the diversion roads we had in place. For a while, it was looking like we would have to build a temporary diversion road and tar this, but we luckily avoided this as it would have increased costs dramatically,” cited Kieran.

Thereafter, the O’Sulllivans completed much of the work themselves alongside Coosheen Construction, with the roadways being concreted and kerbing installed to a high level of finish, along with a 2,700-gallon precast tank for effluent collection being sourced from W& M Kiely Ltd.

The wings of the culverts were built up with stone that had been dug out for roads, which leaves an aesthetically pleasing finish to the job, while a retaining wall was also shuttered and poured. Concrete was sourced from Gloun Stone Quarries. On the main culvert, the earthern banks were replaced, with concrete walls used on the smaller culvert sitting underneath the right of way.

Culverts are 4m in width and have an internal height of 2m (with the 100mm floor). The O'Sullivan's believe no culvert should be narrower for cow flow. \ Donal O' Leary

Key areas to focus on

There were several key areas that the O’Sullivans concentrated their efforts on.

“We always had the cow in mind when we were designing it,” said Cathal. The approaching roads have been kept as flat as possible for cow flow, while 4m wide culverts were used throughout.

“Looking at the cows using it, it is usually two cows side-by-side; you’d rarely get three cows walking across the width of the underpass. I don’t think any culvert should be narrower than 4m, as if cows did get spooked and rushed in to the tunnel, you could have cows getting jammed easily.”

The culverts themselves are 2.1m high, with a 100mm floor poured afterwards.

“We were possibly a bit naive beforehand, as we hadn’t taken on a job like this before. All the companies we worked with were exceptional, with Croom and McCarthys in particular being very professional and knowledgeable surrounding the engineer’s reports, road closures and road

openings.”

The roadway between the two underpasses was angled slightly to avoid taking more of the neighbours' land than was necessary. \ Donal O' Leary

Price

The O’Sullivans completed a good deal of work themselves, which reduced the cost considerably. As it stands, the complete works have come to a total of €166,000 including VAT for the two underpasses. However, VAT is to be reclaimed, and with the O’Sullivans in a partnership and Cathal qualifying for the YFCIS under TAMS, grant aid is yet to be received for the project, so both of these should see the bill considerably reduced. The O’Sullivans were keen to stress that this was not a typical underpass project, with 17 culverts being used and the price likely not reflective of other underpasses.

“It’s a dream to use now and we are extremely happy with the finish. The good will of our neighbours meant a lot to us, and Maurice Downey who gave us part of his field can now use the underpasses as well to move stock to other parts of his farm, which is a little bonus for him. With the main grazing block being the far side of these underpasses, they will be used 270 days plus a year,” stated Kieran.

A 2,700 gallon precast tank was installed at the smaller underpass, with the roadway sloping gently towards this. \ Donal O' Leary

One of the culverts sits under a busy L road along the Wild Atlantic Way, while the other sits under a right of way used by two farmers \ Donal O' Leary

Taking on one underpass is a big enough investment and challenge, but doing two at the same time is an even bigger one. This didn’t seem to faze Kieran and Cathal O’Sullivan, who are farming in partnership in Goleen, Co Cork, where the father-and-son team are milking 180 cows along the Wild Atlantic Way.

Creating underpasses was on Cathal’s mind for many years, with the herd having to cross three separate roads to access the main grazing block. The fact that the farm is on the Wild Atlantic Way meant that tourist traffic, especially in the summer months, proved challenging when moving cows between paddock and parlour.

The decision was made to use two underpasses to alleviate this pressure; one crossing underneath a busy L road, with the other crossing a right of way used by two neighbouring farmers.

Planning was submitted in late 2023 with a TAMS application submitted in Aril 2024 and once some minor issues were resolved, permission was granted. In order to be able to install the two underpasses, the O’Sullivans had to take the corner of a field from their neighbour Maurice Downey, while a ditch also had to be taken down and replaced from neighbour Denis Hellen.

“We can’t thank them both enough, as without their co-operation, we wouldn’t have been able to complete the job,” said Kieran.

The roadway between the two underpasses was angled in such a way to avoid taking more of Maurice’s land than was necessary.

The O’Sullivans employed McCarthy Plant Hire, Skibbereen, as the main contractor as they had all the necessary certification and inusrance to complete the road closures and opening.

The cow was the main priority when it came to designing the underpasses, with sharp angles or ramps eliminated for cow flow. \ Donal O' Leary

Breaking ground

Ground was broken in early December by the O’Sullivans themselves, with the farm having two diggers for working on the holding. Both sides of the culverts were dug beforehand to reduce the workload on the contractor. Stone was dug from a nearby field and stockpiled for the side roads up from the main underpass, as well as for filling around the culverts after insertion.

Planning was key to the success of the job, with the O’Sullivans highly complementary of both Croom Concrete, which supplied the culverts, and McCarthy Plant Hire, which worked in tandem with each other around the road closure dates. The road was broken out on Monday 13 January, as per road closures, with the two roadways cut away and ready for culverts the following evening. Luckily, there were no services where the underpasses were being dug, which simplified the process. The 17 culverts were then hoisted in to position on Wednesday 15 January, with Croom Concrete and Kavanagh Cranes having both underpass culverts fitted by 5pm that evening and the crane sent off. The culverts were then sealed the next day, before the process of back-filling began.

Kieran and Cathal O' Sullivan, Goleen, Co Cork, with the new underpasses the built on the farm. \ Donal O' Leary

Finishing

To ensure that the road surface would be properly compacted, layers of stone fill and 8-0-4 material from Gloun Stone Ltd were laid down in 300mm layers and compacted using wacker plates and vibrating rollers. Ducting was placed during the back-filling to allow water or electricity to be carried through the culverts. The ground surrounding the culverts was good, which meant very little subsidence occurred anyway. A week after the culverts were laid, the road was tarred and reopened on Thursday 20 January, with the road having to be shut for just 10 days in total.

“Neighbours were very good, and didn’t mind using the diversion roads we had in place. For a while, it was looking like we would have to build a temporary diversion road and tar this, but we luckily avoided this as it would have increased costs dramatically,” cited Kieran.

Thereafter, the O’Sulllivans completed much of the work themselves alongside Coosheen Construction, with the roadways being concreted and kerbing installed to a high level of finish, along with a 2,700-gallon precast tank for effluent collection being sourced from W& M Kiely Ltd.

The wings of the culverts were built up with stone that had been dug out for roads, which leaves an aesthetically pleasing finish to the job, while a retaining wall was also shuttered and poured. Concrete was sourced from Gloun Stone Quarries. On the main culvert, the earthern banks were replaced, with concrete walls used on the smaller culvert sitting underneath the right of way.

Culverts are 4m in width and have an internal height of 2m (with the 100mm floor). The O'Sullivan's believe no culvert should be narrower for cow flow. \ Donal O' Leary

Key areas to focus on

There were several key areas that the O’Sullivans concentrated their efforts on.

“We always had the cow in mind when we were designing it,” said Cathal. The approaching roads have been kept as flat as possible for cow flow, while 4m wide culverts were used throughout.

“Looking at the cows using it, it is usually two cows side-by-side; you’d rarely get three cows walking across the width of the underpass. I don’t think any culvert should be narrower than 4m, as if cows did get spooked and rushed in to the tunnel, you could have cows getting jammed easily.”

The culverts themselves are 2.1m high, with a 100mm floor poured afterwards.

“We were possibly a bit naive beforehand, as we hadn’t taken on a job like this before. All the companies we worked with were exceptional, with Croom and McCarthys in particular being very professional and knowledgeable surrounding the engineer’s reports, road closures and road

openings.”

The roadway between the two underpasses was angled slightly to avoid taking more of the neighbours' land than was necessary. \ Donal O' Leary

Price

The O’Sullivans completed a good deal of work themselves, which reduced the cost considerably. As it stands, the complete works have come to a total of €166,000 including VAT for the two underpasses. However, VAT is to be reclaimed, and with the O’Sullivans in a partnership and Cathal qualifying for the YFCIS under TAMS, grant aid is yet to be received for the project, so both of these should see the bill considerably reduced. The O’Sullivans were keen to stress that this was not a typical underpass project, with 17 culverts being used and the price likely not reflective of other underpasses.

“It’s a dream to use now and we are extremely happy with the finish. The good will of our neighbours meant a lot to us, and Maurice Downey who gave us part of his field can now use the underpasses as well to move stock to other parts of his farm, which is a little bonus for him. With the main grazing block being the far side of these underpasses, they will be used 270 days plus a year,” stated Kieran.

A 2,700 gallon precast tank was installed at the smaller underpass, with the roadway sloping gently towards this. \ Donal O' Leary

One of the culverts sits under a busy L road along the Wild Atlantic Way, while the other sits under a right of way used by two farmers \ Donal O' Leary

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: