The Flynn family are lifelong suckler farmers and agricultural contractors based in Naul, Co Dublin. Today, the business is headed up by Pat Flynn having taken over the reins from his late father, Loughlin. Pat is also joined by his son PJ.

Alongside offering a vast range of contracting services – which mainly include round baling, slurry/waste handling and muck spreading – the duo run a 60-cow suckler herd which sees all calves kept on farm until finish.

Background

With a steadily increasing bale count up through the years and running one McHale Fusion baler, Pat looked at ways in which he could increase output without going down the route of investing in a second baler. With more and more farmers tedding too, the purchase of a twin-rotor rake was the obvious solution.

“Up until 2020, we had got away without a rake, baling 10ft swaths,” Pat said. “With more and more customers looking to have grass tedded out after mowing, we decided the time had come to invest in a tedder and twin-rotor rake.”

With no better place to explore the options available on the market than the FTMTA Farm Machinery Show in Punchestown, Pat had a close look at all the major twin-rotor rakes on the market at the 2019 event.

“We hadn’t any ties to a particular brand as such, but we did want to deal where we knew there would be a reliable backup service.

“After studying all closely, we were drawn towards SIP. The build quality throughout the range was an instant attraction. We settled on a Star R (Robust) 650/20 T model and a Malone tedder for the following 2020 season,” Pat explained. In 2023, it was upgraded like for like with a new machine.

Driveline and rotors

Laying claim as being one of the first companies to develop a twin rotor rake, SIP has a long-standing history of rake production going back to the 1970s.

Having secured numerous patents since, the brand has worked hard to develop a range of centre delivery and side delivery machines to suit both contractors and farmers.

With models spanning in working width from 6m to 10m, the 650/20 T sits as the smallest offering within the Star R range of twin rotor centre delivery rakes offered by the Slovenian manufacturer.

In search of a machine to comfortably merge two 10ft swathes of grass or rake up the equivalent of tedded grass, Pat felt it was the 650/20 T model that best suited his needs.

The machine as standard is equipped with hydraulic telescopic width adjustment from 6m to 6.6m (20ft to 22ft). Pat kept its specification simple and choose to avoid the electronic control box which reduces the number of spools required from three to one. Therefore, there are three hydraulic services required: one double acting for the rotor’s telescopic width adjustment and one single acting each for both left and right rotors.

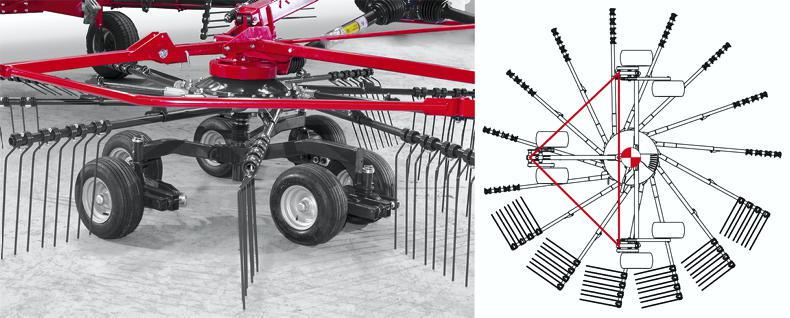

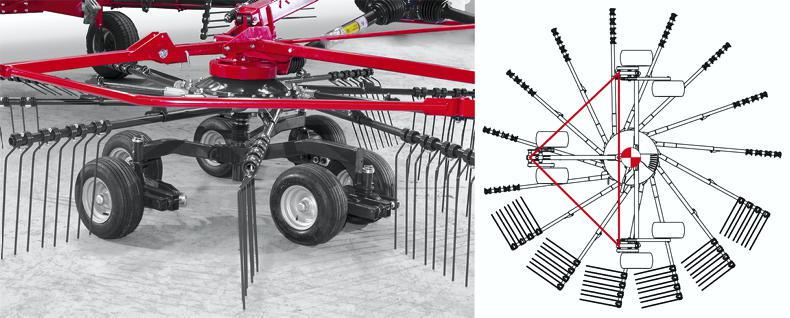

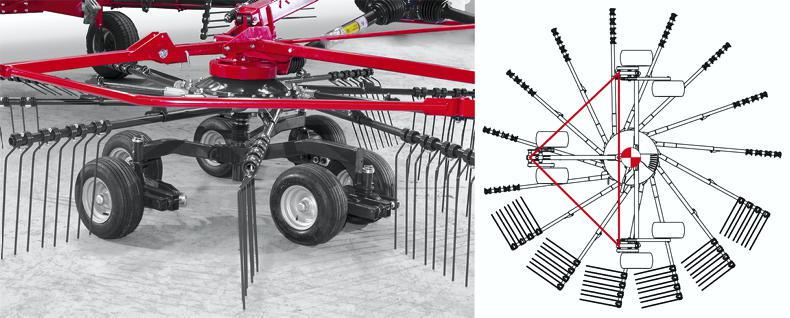

On the Star R 650/20 T, SIP opts to keep things simple and run its driveline below the main chassis via a Walterscheid driveline. Power is split to each rotor via a Y-gearbox, a straightforward approach according to SIP which reduces the load on the PTO shaft. The frame is sturdily built while the steering linkage runs from the headstock on top of the chassis.

Each rotor measures 2.86m in diameter, both of which are equipped with 10 tine arms. Each individual tine arm is then equipped with four double tines. Inside each rotor is a 42cm cast-iron cam track which is seated on the vertical rotor shaft and supported by a double bearing system.

An aluminium casting holds each of the individually replaceable tine arms in place via three bolts. In order to reduce wear, each arm is equipped with two Teflon bushings. Having had a trouble-free experience so far, Pat pointed out that the rotor design appears robust and is smooth running.

The walking tandem rotor bogies leave the pivot point positioned as close to the back of the tine as possible for optimum contour following.

Ground following

A particular feature that impressed Pat was the rakes ground-following ability regardless of terrain. In order to achieve this, SIP uses patented walking tandem rotor bogies whereby the front and rear axles of each are equipped with tandem wheel setups.

Another feature Pat complimented was the fact the rotors have a rear-biased centre of gravity which means the front of the rotor lifts first and lower last resulting in a smoother transition in and out of work – similar to how an aeroplane takes off and lands.

SIP uses a 3D mounting system which allows free movement of the rotors to further aid ground tracking and lateral movement of 10°.

“The working height of each rotors spring tines is manually adjustable but to be fair, we haven’t seen a need to have it any other way. We put some time into setting it right on day one and haven’t had to touch it since,” Pat said.

Swath

“I quickly formed the opinion that a good rake man can make a bad baler man look good and a bad rake man can make a good baler man look bad,” Pat said.

“The formation and shape of the row/swath is critical if you want to make good bales. It needs to be wide with an even amount of grass trhoughout. A narrow or pointed row of grass will only lead to egg shaped bales.”

Regardless of the chosen working width, Pat has the rotor cam tracks set to leave as wide and as even of row possible for his Fusion 4 baler.

The cam track is adjustable ± 30° allowing plenty of adjustment to suit the crop and user.

Verdict

“Prior to going down the route of buying a rake, I was a little nervous about running costs given the number of moving parts combined with rough ground etc.

But, in all honesty raking the best part of 15,000 bales each year as well as some straw, I’m impressed. Its a well built machine from front to back. Aside from a couple of tines to no fault of the machine is all that we’ve had to replace. I will say that correct setup and the operator both have a big influence on a rakes performance and reliability.

We seen major benefits instantly when we moved to the rake, it was as good as a second baler in terms of output as we were doing half the driving around fields lifting 20ft rows instead of 10fts.

Now that the majority of grass is tedded, we decided to buy a 10ft side mounted plain SIP mower of Maher Tractors for the coming season”, Pat said.

“Prior to going down the route of buying a rake, I was a little nervous about running costs given the number of moving parts combined with rough ground etc.

“But, in all honesty raking the best part of 15,000 bales each year as well as some straw, I’m impressed. It’s a well built machine from front to back. Aside from a couple of tines, to no fault of the machine, is all that we’ve had to replace. I will say that correct setup and the operator both have a big influence on a rake’s performance and reliability.

“We’ve seen major benefits instantly when we moved to the rake, it was as good as a second baler in terms of output as we were doing half the driving around fields lifting 20ft rows instead of 10fts.

“Now that the majority of grass is tedded, we decided to buy a 10ft side mounted plain SIP mower off Maher Tractors for the coming season”, Pat said.

Model: Star R 650/20 TWorking width: 6-6.6mSwath width: 0.9m-1.6mNo of tines per rotor: 10Weight: 1,700kgTransport height: 3.88m Transport width: 2.55mTyres: 340/55 R17Starting price: €25,000 plus VAT

The Flynn family are lifelong suckler farmers and agricultural contractors based in Naul, Co Dublin. Today, the business is headed up by Pat Flynn having taken over the reins from his late father, Loughlin. Pat is also joined by his son PJ.

Alongside offering a vast range of contracting services – which mainly include round baling, slurry/waste handling and muck spreading – the duo run a 60-cow suckler herd which sees all calves kept on farm until finish.

Background

With a steadily increasing bale count up through the years and running one McHale Fusion baler, Pat looked at ways in which he could increase output without going down the route of investing in a second baler. With more and more farmers tedding too, the purchase of a twin-rotor rake was the obvious solution.

“Up until 2020, we had got away without a rake, baling 10ft swaths,” Pat said. “With more and more customers looking to have grass tedded out after mowing, we decided the time had come to invest in a tedder and twin-rotor rake.”

With no better place to explore the options available on the market than the FTMTA Farm Machinery Show in Punchestown, Pat had a close look at all the major twin-rotor rakes on the market at the 2019 event.

“We hadn’t any ties to a particular brand as such, but we did want to deal where we knew there would be a reliable backup service.

“After studying all closely, we were drawn towards SIP. The build quality throughout the range was an instant attraction. We settled on a Star R (Robust) 650/20 T model and a Malone tedder for the following 2020 season,” Pat explained. In 2023, it was upgraded like for like with a new machine.

Driveline and rotors

Laying claim as being one of the first companies to develop a twin rotor rake, SIP has a long-standing history of rake production going back to the 1970s.

Having secured numerous patents since, the brand has worked hard to develop a range of centre delivery and side delivery machines to suit both contractors and farmers.

With models spanning in working width from 6m to 10m, the 650/20 T sits as the smallest offering within the Star R range of twin rotor centre delivery rakes offered by the Slovenian manufacturer.

In search of a machine to comfortably merge two 10ft swathes of grass or rake up the equivalent of tedded grass, Pat felt it was the 650/20 T model that best suited his needs.

The machine as standard is equipped with hydraulic telescopic width adjustment from 6m to 6.6m (20ft to 22ft). Pat kept its specification simple and choose to avoid the electronic control box which reduces the number of spools required from three to one. Therefore, there are three hydraulic services required: one double acting for the rotor’s telescopic width adjustment and one single acting each for both left and right rotors.

On the Star R 650/20 T, SIP opts to keep things simple and run its driveline below the main chassis via a Walterscheid driveline. Power is split to each rotor via a Y-gearbox, a straightforward approach according to SIP which reduces the load on the PTO shaft. The frame is sturdily built while the steering linkage runs from the headstock on top of the chassis.

Each rotor measures 2.86m in diameter, both of which are equipped with 10 tine arms. Each individual tine arm is then equipped with four double tines. Inside each rotor is a 42cm cast-iron cam track which is seated on the vertical rotor shaft and supported by a double bearing system.

An aluminium casting holds each of the individually replaceable tine arms in place via three bolts. In order to reduce wear, each arm is equipped with two Teflon bushings. Having had a trouble-free experience so far, Pat pointed out that the rotor design appears robust and is smooth running.

The walking tandem rotor bogies leave the pivot point positioned as close to the back of the tine as possible for optimum contour following.

Ground following

A particular feature that impressed Pat was the rakes ground-following ability regardless of terrain. In order to achieve this, SIP uses patented walking tandem rotor bogies whereby the front and rear axles of each are equipped with tandem wheel setups.

Another feature Pat complimented was the fact the rotors have a rear-biased centre of gravity which means the front of the rotor lifts first and lower last resulting in a smoother transition in and out of work – similar to how an aeroplane takes off and lands.

SIP uses a 3D mounting system which allows free movement of the rotors to further aid ground tracking and lateral movement of 10°.

“The working height of each rotors spring tines is manually adjustable but to be fair, we haven’t seen a need to have it any other way. We put some time into setting it right on day one and haven’t had to touch it since,” Pat said.

Swath

“I quickly formed the opinion that a good rake man can make a bad baler man look good and a bad rake man can make a good baler man look bad,” Pat said.

“The formation and shape of the row/swath is critical if you want to make good bales. It needs to be wide with an even amount of grass trhoughout. A narrow or pointed row of grass will only lead to egg shaped bales.”

Regardless of the chosen working width, Pat has the rotor cam tracks set to leave as wide and as even of row possible for his Fusion 4 baler.

The cam track is adjustable ± 30° allowing plenty of adjustment to suit the crop and user.

Verdict

“Prior to going down the route of buying a rake, I was a little nervous about running costs given the number of moving parts combined with rough ground etc.

But, in all honesty raking the best part of 15,000 bales each year as well as some straw, I’m impressed. Its a well built machine from front to back. Aside from a couple of tines to no fault of the machine is all that we’ve had to replace. I will say that correct setup and the operator both have a big influence on a rakes performance and reliability.

We seen major benefits instantly when we moved to the rake, it was as good as a second baler in terms of output as we were doing half the driving around fields lifting 20ft rows instead of 10fts.

Now that the majority of grass is tedded, we decided to buy a 10ft side mounted plain SIP mower of Maher Tractors for the coming season”, Pat said.

“Prior to going down the route of buying a rake, I was a little nervous about running costs given the number of moving parts combined with rough ground etc.

“But, in all honesty raking the best part of 15,000 bales each year as well as some straw, I’m impressed. It’s a well built machine from front to back. Aside from a couple of tines, to no fault of the machine, is all that we’ve had to replace. I will say that correct setup and the operator both have a big influence on a rake’s performance and reliability.

“We’ve seen major benefits instantly when we moved to the rake, it was as good as a second baler in terms of output as we were doing half the driving around fields lifting 20ft rows instead of 10fts.

“Now that the majority of grass is tedded, we decided to buy a 10ft side mounted plain SIP mower off Maher Tractors for the coming season”, Pat said.

Model: Star R 650/20 TWorking width: 6-6.6mSwath width: 0.9m-1.6mNo of tines per rotor: 10Weight: 1,700kgTransport height: 3.88m Transport width: 2.55mTyres: 340/55 R17Starting price: €25,000 plus VAT

SHARING OPTIONS